Thermal Barriers

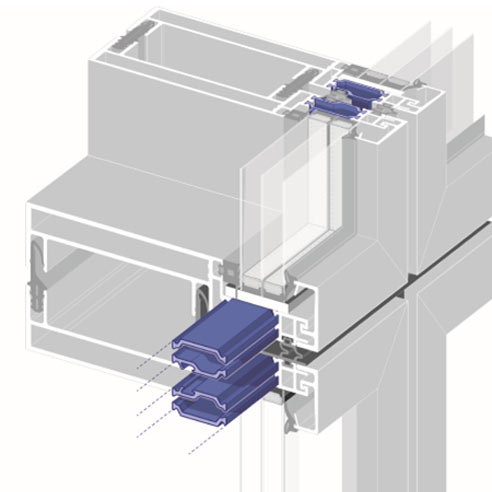

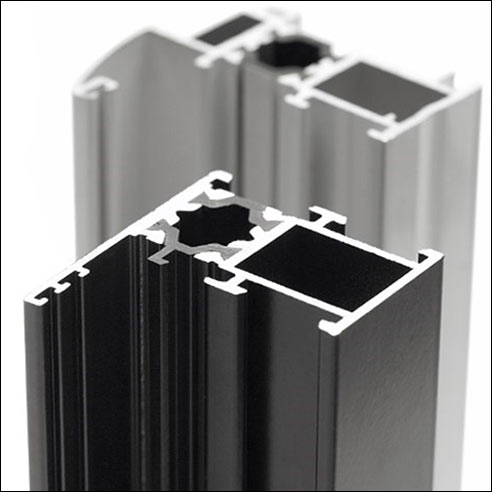

Aluminum has many excellent properties, but insulation isn’t one of them. It conducts heat, causing variations in temperatures. Enter our specialized thermal breaks. Used in exterior windows, doors, and supermarket coolers, they expertly insulate, ensuring no thermal transfer. With Azo-Brader at your disposal, expect the best in pour & debridge and skip debridge applications.

Why Choose Us?

Bonnell Aluminum is a leading extruder, fabricator, and finisher of top-tier aluminum extrusions across North America. Our barrier designs guarantee strength, thermal efficiency, and cost-effectiveness for every venture.

Products Tailored to Your Needs:

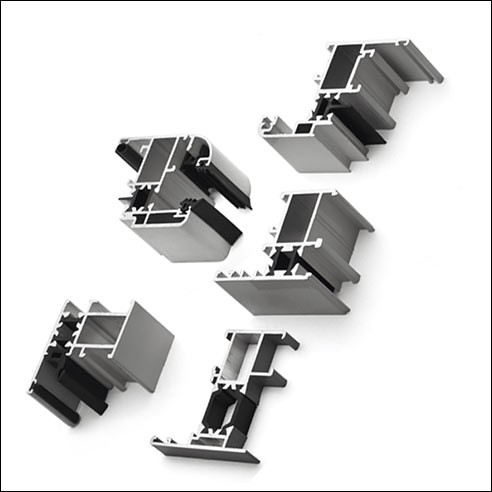

Thermal Bar: The epitome of design flexibility. Get dual-finish at the price of single-finish. Enjoy unmatched insulation and robustness for windows, doors, and more.

Skip Debridge: Looking for peak structural integrity in one-color setups? This system is your match. Ideal for single-color curtain walls and weight-bearing windows.

Pour and Debridge: When strength meets affordability. Perfect for standard applications, ensuring thermal management without compromising on costs.

Azo-Brading: Elevate your thermal breaks with our Azo-Brading process. Ensuring the chemical barrier stays intact, we’re so confident in its quality, we've backed it with a 10-year warranty.

Join us in making your projects thermally efficient and incredibly strong. Your trust is our commitment to excellence beyond extrusion.

Please submit the form below to request more information on this capability.