blog & educational outreach

Making Today's Tight Labor Market Work to Your Advantage

Can you actually make today’s tight labor market work to your advantage?

Labor challenges have always been a part of the manufacturing industry, but during the recent pandemic, it’s harder than ever to find the skilled laborers you need to keep your operation running. Read this brief article for 3 practical ways to proactively approach these challenges and ensure that any labor problems are put in check.

We’ve all heard about a shortage of trade labor, but what does it mean?

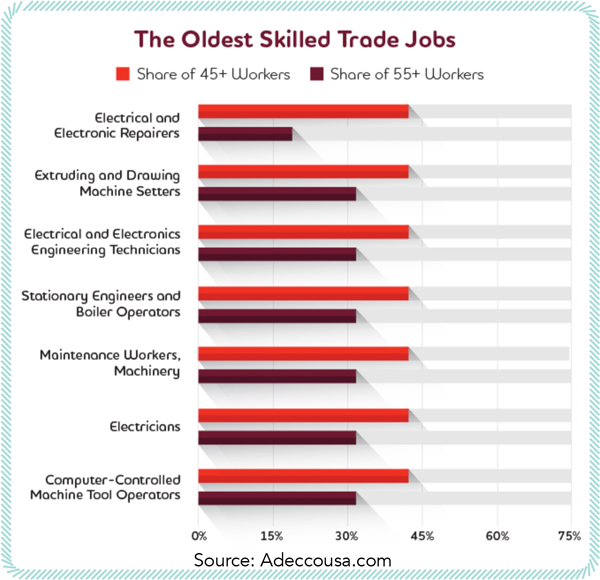

Trade labor shortages are certainly not a new problem; it’s been going on for years. Mostly traced back to the recession of 2008 when there was a severe loss of trade jobs, the issue has worsened a dozen years later. Other factors that contribute to this shortage include high levels of retirement among Baby Boomers, largescale infrastructure projects that have been ignored (and now require tradespeople to close the gap), and fewer trade programs in schools to prepare students for a trade career.

Even the decline of unions, with their “career ladders”, has impacted this trade gap. This issue has been especially prevalent to those in the aluminum industry. In fact, a Deloitte study found that the skills gap may leave an estimated 2.4 million positions unfilled between 2018 and 2028, with a potential economic impact of $2.5 trillion.

So how does this affect your business?

Aluminum manufacturing, in this especially unsettling time, has been designated as essential by the US Department of Commerce. That puts an even larger burden on the sector to produce under labor shortages. With a dwindling resource pool to pull from, businesses must rely on a different set of tactics to manage the lack of available skilled trade labor.

Following are three approaches to help your business address current labor shortages and gain efficiencies in your operation:

THREE WAYS TO ADAPT TO LABOR SHORTAGES

Either individually or through a community or industry cooperative, a pipeline can be built to entice individuals to learn your business and grow into a skilled position.

If you don’t have a program of your own, consider joining forces with programs fostered by trade associations you belong to, programs sponsored by local high schools, and other like-minded local employers. Many companies report a high degree of retention from employees brought through a structured apprenticeship.

By networking within associations and your community, you can discover common ground and encourage programs that help refine your own practices.

At times, recruitment processes, although with best intentions, focus on the wrong things. You certainly don’t want to incur the cost of a bad hire, but sometimes candidates are eliminated too quickly based on instinct.

Focus on intangible skills like drive, loyalty, and sense of purpose. Let an individual tell you their story; why are they here and what do they hope to accomplish. After all, you can train for the job requirements, but not for personality.

Consider your business culture when hiring. This is another soft skill, but a bad match can lead to disappointment further down the road. If the individual will not mesh with your current team, then either the team culture or the individual is wrong for the business.

Change the way you think about diversity. Age, heritage, race, disabilities and other “differences” often cause individuals to be overlooked. Another area where there has been a clear bias against applicants is criminal history and immigration status. Hire the right individual rather than focusing on how they are different.

If your current team is performing process steps that can easily be handled by a vendor then analyze the cost/benefit of such an action.

Often, we look at this type of work-crew enhancement as one-sided. It will cost $X more to do it that way without looking at what it may free up on the shop floor. If you are paying someone $20 an hour to execute the added steps, consider what that savings could be in dollars and also increased productivity. If that worker is free of the task, they can be assigned to other WIP that can boost throughput.

You could isolate assembly, kitting and packaging down to your base cost and weigh it against vendor execution. Perhaps the vendor can perform these steps, including an extra quality assurance check, and then ship directly to your customer on your behalf.

Other areas to consider include machining, drilling, bending, extrusion, painting and other value-added services that large vendors can perform for you.

Being Proactive

As in most cases that affect our livelihood, business owners need to act and change in order to ensure success. If the past decade has taught us anything, it’s that inaction can lead to failure.

“The only man who never makes mistakes is the man who never does anything.”

-Theodore Roosevelt